Home < News < DESIGNING OF BUILDING SEISMIC ISOLATION-lead rubber bearing,high damping rubber bearing, Seismic damper

DESIGNING OF BUILDING SEISMIC ISOLATION SYSTYM- -lead rubber bearing,high damping rubber bearing, Seismic damper

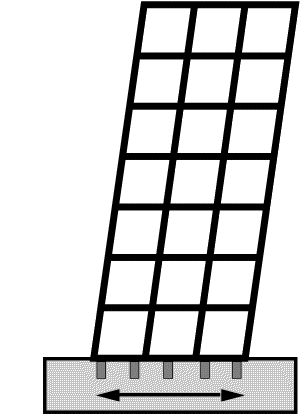

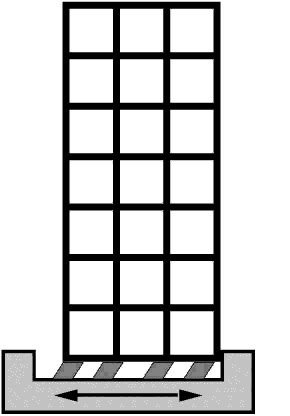

As an effective passive control method, base-isolated structure can significantly reduce the seismic response of the structure by adjusting the natural vibration period of the original structure system to keep it away from the predominant period of the earthquake ground motion.

Because of its small horizontal stiffness, the isolation system can extend the period of the superstructure to more than 3s, which greatly reduces the acceleration response of the building due to the earthquake. At the same time, the isolation system can also use the nonlinear deformation of the isolation bearing to absorb the seismic energy and the energy consumption of the additional viscous damper to improve the damping ratio of the system, thus reducing the earthquake force on the building.

without seismic system with base seismic isolation

As a manufacturer of seismic isolation bearing, we need to understand the follow engineering conditions so that we can provide accurate quotations and corresponding services.

1. If we are entrusted to design with the analysis of building isolation system, We need following information of the building , and we will submit it to our designing department for analysis and design the building isolation system.

① building name and address

① Seismic fortification standard grade

② Designed ground motion acceleration

③ Site type

{Class I site: rock, dense gravel soil.

Class II site: medium-density and loose gravelly soil, dense and medium-density gravel, coarse and medium sand; Cohesive soil with allowable bearing capacity of foundation soil>150kPa.

Class III site: loose gravel, coarse and medium sand, dense and medium density fine silt, cohesive soil with allowable bearing capacity of foundation soil ≤ 150kPa and fill soil ≥ 130kPa.

Class IV site: muddy soil, loose fine silt, newly deposited cohesive soil; Fill with allowable bearing capacity of foundation soil<130kPa.}

④ building drawing, and Foundation distribution diagram

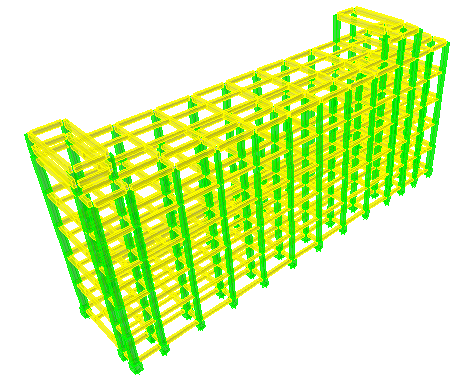

We will establish a model for stress and seismic analysis, and make the design quotation first.

We will build a model according to the provided buildings and geological conditions, conduct seismic analysis, and then design the corresponding isolation system, as shown in the following figure. In this process, the cooperation of the building designer is required

2. If we are only going to produce seismic isolators according to the product data provided(no need design), and provide the quotation, production and testing process, we need follow parameters.

drawing with dimensions | Yield strength | yield stiffness | damping ratio | displacement |

We will design structure and provide our offer.

In the production and testing, we will send details of process.