1. Overview

In order to meet the requirements for safe operation of high-speed trains and passenger comfort, the design of high-speed railway bridges has made more stringent regulations in terms of some principle regulations, design live loads, structural deformation limits, structural construction requirements and maintenance and maintenance.

2. General provisions and principles for high-speed railway bridge design

2.1 High-speed railway bridge and culvert design focuses on structural durability design

The experience of using a large number of bridges shows that the durability of the structure plays a decisive role in the safe use and economy of the bridge. Economic rationality should minimize the sum of construction costs and inspection and maintenance costs during the service period.

The Beijing-Shanghai high-speed railway is the first high-speed passenger line built in my country. It has large traffic volume and high technical standards. It will be built into a world-class railway. In order to ensure that the trains can operate normally without restrictions, the bridge structure of the high-speed railway has sufficient durability. is a necessary guarantee.

(1) The flood frequency standards for bridges on high-speed railways shall be based on the standards for Class I trunk lines, the highest level of railway trunk lines. And the design frequency standard for culverts has been raised to 1/100. This regulation has little impact on culverts in plain areas, but for flood drainage culverts in hilly areas, some need to increase the hole diameter or change them to beam bridges.

(2) Although ordinary railways have requirements for the durability of bridge and culvert structures, the "Interim Regulations" clearly state that the main load-bearing structures of bridges should be designed according to 100-year service requirements.

(3) Uniformly consider the reasonable structural layout and structural details, emphasizing that the structure should be easy to inspect and repair to ensure the safe use of the bridge.

2.2 High-speed railway bridges and culverts have good dynamic performance

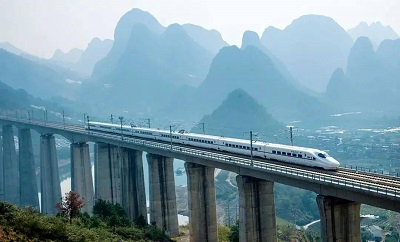

Under the operating conditions of high-speed trains, the dynamic response of the bridge structure is intensified, which makes the safety of train operation, passenger comfort, load impact, material fatigue, train operation noise, structural durability and other issues different from those of ordinary railways. Therefore, the bridge structure must have sufficient strength and stiffness, ensure reliable stability and maintain a high smoothness of the track on the bridge, so that the bridge structure of the high-speed railway can withstand large dynamic effects and have good dynamic characteristics.

2.4 The form of concrete beam structure of high-speed railway is mainly box-shaped section

2.4.1 Medium and small span concrete beam structure

The superstructure of the bridge directly bears the train load. Since the dynamic response is intensified when high-speed trains are running, in order to ensure the safety of train operation and passenger comfort, the vertical stiffness, lateral stiffness and torsional stiffness of the superstructure are strengthened to meet the stiffness limit. It is very necessary to meet the requirements and at the same time strengthen the integrity of the structure to improve the dynamic characteristics of the structure.

2.4.2 Bridges with spans of 16m and below

For bridges with a span of 16m and below, reinforced concrete frame bridges and reinforced concrete rigid frame continuous bridges can be used. These structures can meet the requirements of high-speed driving. Reasonable structural types can be selected based on the actual situation and construction conditions of the work site.

2.5 Selection of high-speed railway beam types

2.5.1 Simply supported beam

The porous equal-span simply supported girder bridge has the same span shape, the same cross-section, and unified structural layout, which facilitates the daily inspection, maintenance and repair of the structure.

Girder bridges using simply supported systems are better suited to areas with poor geology and low foundation bearing capacity.

Simply supported beams with equal spans require a large amount of work and are suitable for on-site factory prefabrication and erection hole by hole, which can significantly increase the construction speed.

2.5.2 Continuous beam

The continuous beams arranged with porous equal spans can improve the structural integrity and stiffness of the beams, and are more conducive to maintaining the smoothness of the lines on the bridge, thus improving the comfort and safety of driving on the bridge. Adopting appropriate construction methods can ensure the economy and construction progress of the bridge.

The design conditions for continuous beams with commonly used spans of 24m and 32m on the Beijing-Shanghai high-speed railway are based on the uneven settlement of adjacent piers and abutments of 1cm. Therefore, continuous beams with commonly used spans of 24m and 32m are more sensitive to foundation settlement.

3. High-speed railway bridge design loads

3.1 Load combination

The relevant load content of high-speed railways is based on the current design specifications for railway bridges and culverts, with necessary revisions and supplements based on the characteristics of high-speed railway bridge and culvert design. The design calculation method still uses the allowable stress method, and the load classification and load combination principles still follow the provisions of the railway bridge and culvert design specifications. However, based on the actual situation of high-speed driving and the use of seamless lines, a long list of load items has been added. The longitudinal horizontal force of the rail, the rail breaking force of the long rail and the aerodynamic force caused by high-speed driving.

The bridge expands and contracts due to temperature changes and deflects due to train loads. This deformation of the bridge is constrained by the track structure. Due to the continuity of the seamless lines on the bridge, when the beam deforms, the rails produce two longitudinal horizontal forces, called telescopic force and deflection force. At the same time, the two forces also react on the beam and are transmitted to the supports. and piers. Telescopic force and deflection force are both main forces, but they will not be generated at the same time on the same track.

The seamless rails on the bridge may break due to fatigue, excessive longitudinal force or damage due to other reasons, thus generating a rail-breaking force. The rail-breaking force is calculated based on the sum of the longitudinal resistance of the line within the length of a span of simply supported beams or a continuous beam. The maximum rail-breaking force does not exceed the maximum temperature tensile force value. Under normal operation and maintenance conditions, the probability of rail breakage is relatively small, and the value of the rail breakage force is relatively large. Therefore, it is stipulated that regardless of single-line or double-line bridges, only the rail breakage force of one rail is calculated and treated as a special load. , called the long rail rail breaking force. In the load combination, only its combination with the main force is considered, and not with other additional forces.

Aerodynamic force refers to the movement of surrounding air when a high-speed train is running, resulting in train wind that generates fluctuating pressure on buildings adjacent to the train. It is closely related to the shape and speed of the train, the distance between the adjacent building and the line, and the height of the building. height and other factors. The train wind pressure takes the form of positive and negative pressure waves. Aerodynamic force is the main force. The role of aerodynamic force is mainly used in the structural design of sound barriers. For sound barriers, the most unfavorable aerodynamic force is suction.

5 bridge bearing

For high-speed railway bridges, due to the dynamic effects such as the longitudinal force of the long rail, braking force, train dynamic effect and rolling stock lateral swing force, which are more severe than those of ordinary railway bridges, new requirements are put forward for the vibration damping performance of the bearings. The types of bearings currently used on bridges at home and abroad have changed from mainly steel bearings to various types of rubber bearings. An important reason is that rubber bearings not only have good elasticity, but also have both strength and toughness. It is relatively high and can meet the requirements of bearing power and deformation. It can also meet the requirements for shock and vibration reduction and ride comfort under high-speed driving conditions. The hinged axis slide steel bearing is easy to maintain and has a longer service life than the basin bearing. For small and medium-span bridges, rubber bearings with measures to prevent lateral movement of the structure can be used. For continuous beams and steel beams with larger spans, hinged axis slide steel supports can be used.

In order to facilitate adjustment and replacement, there must be a suitable position and space between the beam and the top of the pier to facilitate the operation of the top beam equipment.

For bridges whose settlement is difficult to control, the guarantee rate of the actual settlement value being within the calculated settlement value is less than 100%, so adjustable supports should be installed to compensate for unforeseen settlement overruns.