Spherical highway bridge bearing, also known as spherical bearings or PTFE spherical bearing, are designed to ensure that vertical and horizontal forces are transmitted under control and is a bearing with low friction, excellent adjustment characteristics, and large slewing capabilities. Spherical bridge bearings feature a high-strength steel body and are designed for high vertical, horizontal and lateral loads and where large rotational structural displacements need to be accommodated. The friction coefficient of bearing design, under the condition of PTFE plate with silicone grease lubrication, when the stress is about 30MPa, the values are as follows: normal temperature 0.03, low temperature 0.05.

Product Detail

1. Main technical performance

Vertical bearing capacity

There are 16 grades vertical bearing capacity

1000-20000KN.

The design rotation angles of bearings are 0.01, 0.015 and 0.02 rad.

The design displacement of bearing is ± 50 - ± 200 mm,

The displacement can be designed according to the needs of the project

The friction coefficient of bearing design, under the condition of PTFE plate with silicone grease lubrication, when the stress is about 30MPa, the values are as follows: normal temperature 0.03, low temperature 0.05

Horizontal force

The transverse horizontal force of the longitudinal movable bearing is 10% of the vertical bearing capacity , and the horizontal force of the fixed bearing is 10% of the vertical bearing capacity.

2. Spherical highway bridge bearing structure

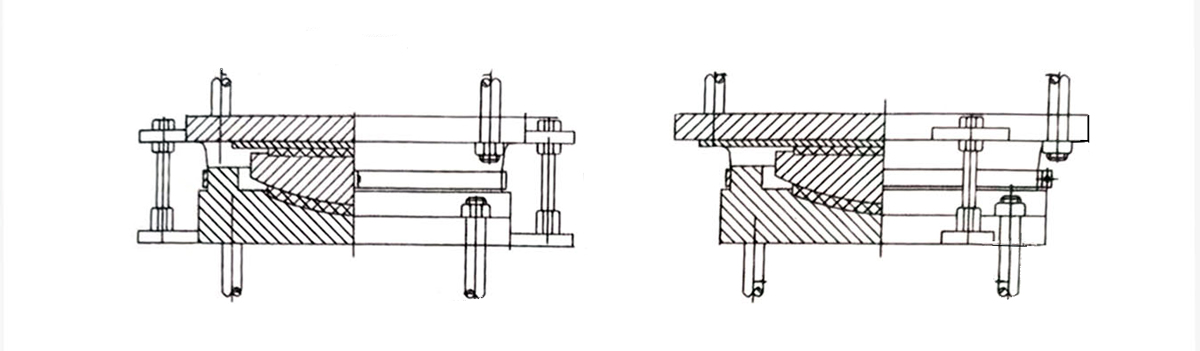

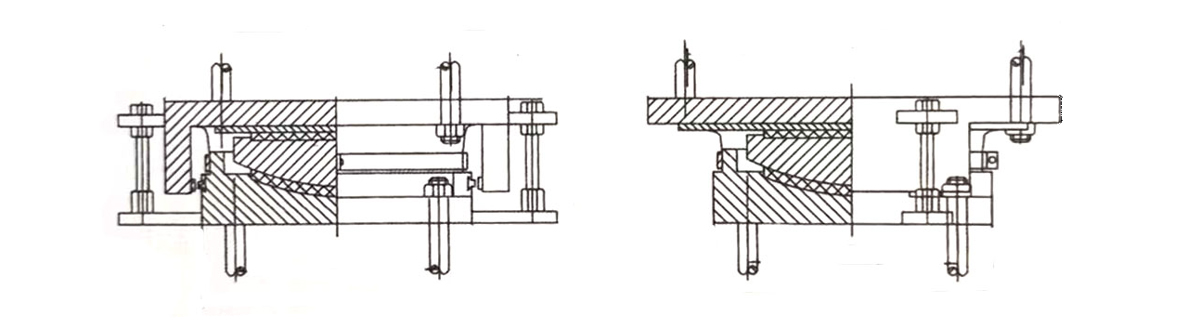

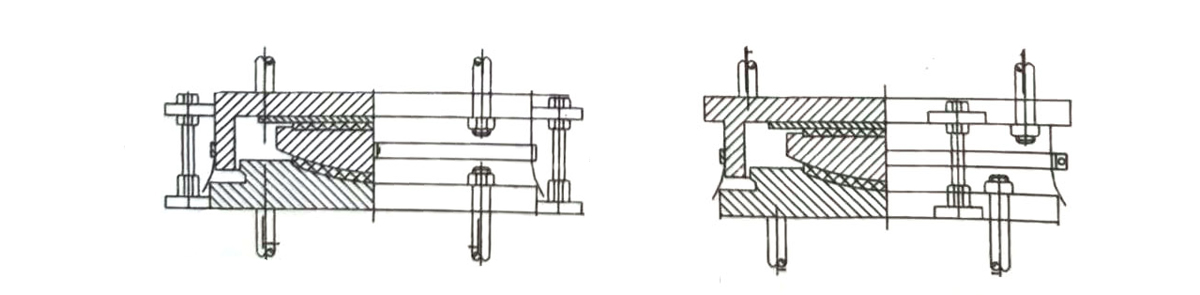

Spherical highway bridge bearing type

Composed of steel plates with edge sliding guides and stainless steel panels for sliding control, similar to pot bearings, spherical highway bridge bearings can also be divided into fixed spherical bearings, guided spherical bearings and free sliding spherical bearings.

1. Fixed type. Only the ability to rotate from any direction is provided.

2. Guided type (one-way sliding). Rotation plus movement in one direction.

3. Free sliding (multi-directional sliding). Rotation plus motion in all directions.

Spherical bridge bearing parts

1. Bottom plate: The steel plate of the bearing assembly attached to the structural concrete/steel member at the top and bottom.

2. Backing plate: A steel plate that restricts low friction sliding materials (such as PTFE, etc.). Metal protrusions that guide the top plate lock with adjacent steel components, limiting the movement of the bearing in the vertical direction.

3. Mating Surfaces: Flat or curved hard smooth surfaces in stainless steel, polished steel or chrome-plated slide with PTFE (polytetrafluoroethylene) or other low friction thermoplastics.

4. Sliding surface: PTFE or UHMWPE (Ultra High Molecular Weight Polyethylene) low friction thermoplastic is mounted on a flat or curved backing plate to provide low friction sliding with mating surfaces.

5. Sliding interface: The combination of mating and sliding surfaces provides relatively low friction sliding displacement.

Spherical bridge bearing application

Spherical bridge bearings are designed for bridges or structures requiring very high vertical, horizontal and lateral loads.

Spherical bridge bearings can be used for different complex bridges, such as curved bridges, inclined bridges, right bridges, RC bridges, PC bridges, steel bridges, railway bridges, easy-to-fall bridges, end-stayed bridges, etc.

Applicable bridge conditions: large corner bridges, wide curved bridges, large torsion bridges, low temperature bridges below -30 °C, etc.

As one of the leading spherical bearing suppliers, Yongxi provides high performance spherical bridge bearing parts and seismic isolations with exellent product quality and aftersales service. If you are looking to buy spherical bearings with factory supply price, welcome to contact us!

3. Characteristic

The spherical bearing has reliable force transmission and flexible rotation. It not only has the characteristics of large bearing capacity and large displacement of basin bearing, but also can better meet the needs of large rotation angle of bearing.

The spherical bearing transmits force through the spherical surface without force necking, and the reaction force acting on the concrete is relatively uniform,

The spherical bearing realizes the manufacturing rotation process through the sliding of the spherical Teflon plate. The rotation torque is small, and the rotation torque is only related to the spherical radius of the bearing and the friction coefficient of the Teflon plate, and has nothing to do with the rotation angle of the bearing. Therefore, it is especially suitable for the requirements of large rotation angle, and the design rotation angle can reach more than 0.05 rad.

The bearing does not use rubber to bear pressure, and there is no influence of rubber aging on the rotation performance of the bearing. It is especially suitable for low temperature areas

The bearing tonnage of this series of bearings and the maximum support reaction force can exceed 100000 KN

The angle is large, and the maximum angle is 0.06 rad

The corrosion resistance is greatly enhanced and can be used in harsh environments such as marine atmosphere and splash zone

The plane sliding and rotating friction resistance is small

Good dustproof and waterproof performance, which can ensure no corrosion and pollution in friction.

The design life is long and can be designed as 100 years.

The support is small and light, which is 40% - 50% lighter than the basin support with the same support reaction force and 20% - 25% lighter than other series of spherical supports with the same support reaction force.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.