Home < News < The installation difference between PTFE sliding bearings and ordinary bridge rubber bearings

The installation difference between PTFE sliding bearings and ordinary bridge rubber bearings

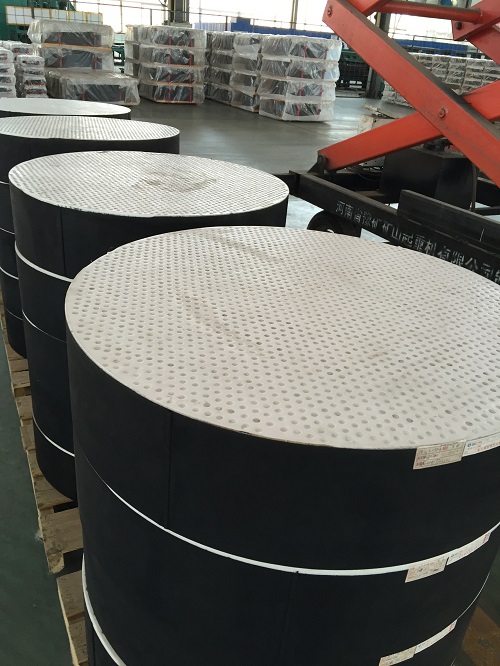

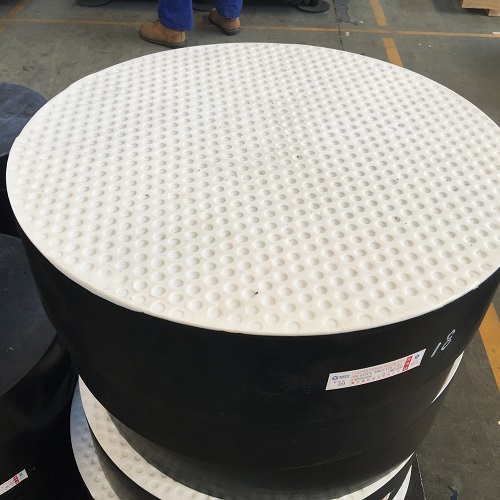

Key words: PTFE sliding bearing, bridge rubber bearing, PTFE rubber bearing

Compared to ordinary rubber bearings, PTFE sliding rubber bearings are also widely used, several precautions need to be taken during installation:

1. The the function of the PTFE rubber bearings is as a movable support and should be matched with a regular rubber bearing pad (used as a fixed support).

2. When installing the PTFE sliding rubber bearing, careful attention must be paid. The PTFE rubber bearing should be accurately positioned according to the designed support center. The steel plate at the bottom of the beam should be parallel and flat with the top surface of the supporting pad stone (or lower steel plate), and should be tightly adhered to both the upper and lower parts of the support; The supports of the same beam are located on the same plane to avoid eccentric compression, uneven support, and individual voids of the sliding rubber bearing.

3. If any problems are found and need to be adjusted after the installation of the PTFE sliding rubber bearing,, the beam end can be lifted and a layer of epoxy resin mortar can be laid between the bottom surface of the PTFE sliding rubber bearing and the support pad stone (or lower steel plate) for adjustment.

4. The oil storage pit on the surface of the rubber support of the PTFE rubber bearing should be filled with non volatile "5201 silicone grease" as a lubricant during installation to reduce the friction coefficient.

5. The stainless steel surface in contact with the PTFE plate should not be damaged or roughened to avoid increasing the friction coefficient and damaging the PTFE sliding plate.

6. When the beam is dropped, in order to prevent horizontal bridge sliding between the beam and the rubber sliding bearing, it is advisable to use wooden triangular blocks to position it on both sides of the beam body. After all the beam dropping work is completed, it should be removed.

7. In order to prevent lafteral sliding o the beam (upper structure), anti-skid blocks should be installed on both sides of the rubber bearings or upper structure.

8. The position of PTFE rubber bearings and stainless steel plates depends on the local temperature during installation. If the stainless steel plate has sufficient length, it can be placed in any season according to the distance between the bearings and the center of the stainless steel plate in spring and autumn.