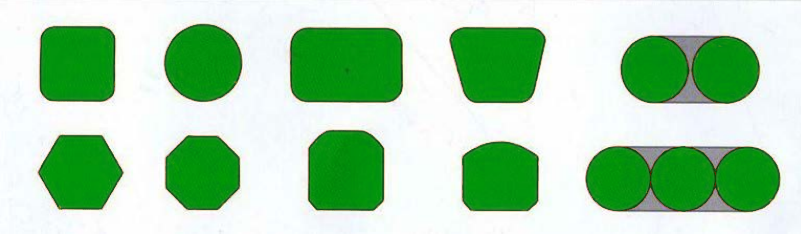

Culvert Balloon is a kind of cylinder bag that can expand, shrink, used to form concrete component of cavity. It is easy to be used, convenient and durable, is soft and can fold, curly, contraction when it isn't inflate, it have the enough strength to withstand the pressure of concrete when it is inflated, this is incomparable with any traditional template, it is used in reinforced concrete members, including stake roof, roof board column, beam, building, water conservancy project(shipyards slipway, dock). Construction practice proves that culvert rubber airbag is simple, not only save materials. And has a shape characteristics, it could be round, Oval, rectangle, vaulted, trapezoidal pipeline. etc. Also you can make a straight hole, etc. can make a building structure light, thin wall hollow. Change the concrete performance have been used rigid characteristic template situation.

Product Detail

Made from rubber and high-strength fiber cloth vulcanization as Inner mold Culvert balloons, also known as formwork rubber airbag or culvert rubber airbag, is a kind of inflatable, shortened and different shapes. It is mainly applied pouring and forming engineering of highway bridge concrete and culvert sewage works. As a professional culvert balloons and rubber products supplier, Yongxi has cooperated with customers around the world, like Mongolia, Indonesia, Kenya, Pakistan, Southeast Asia etc. Welcome to select your interested products and contact us if you have any questions!

1. Easy to use and disassemble. The formwork rubber airbag is an inflatable product which can be poured into hollow components of various finished products, according to different construction projects.

2. Good aging resistance. Made of synthetic rubber, natural rubber and fiber reinforcement after vulcanization, culvert balloons not only have good anti-expansion strength, but also elasticity and flexibility. It can be used in construction under various working conditions.

3. Necessary conditions for the lightweight construction. Due to the use of formwork rubber airbag to reduce the weight of the upper structure of the building and bridge, the pile foundation can be shortened, the span can be increased, and the on-site construction is simple.

4. Suitable for a wide range of temperatures. The material of culvert balloons will not change in the range of -10°C to +90°C.

1. Concrete pouring for highway bridge culvert

2. Sewage discharge projects

3. Tunnel Bridge Side ditch construction.

4. Architectural engineering.

5. Irrigation works.

6. Piles, roof trusses, roof plate columns, beams, etc.

1. Diameter: From0.2m to 3m

2. Total Length: From 1m to 28m

3. Other specification also available upon customer's request.

| Items | Index |

| Thickness tolerance(mm) | 3.2±0.2 |

| Hardness(Shore A) | 65±5 |

| Adhesive tension of rubber and fabric, N/25mm | ≥8 |

| Tensile strength, MPa | ≥12 |

| Elongation at break, % | ≥350 |

| Suitable temperature, °C | -10~80 |

| Appearance | No cracks and no bubbles on the surface, The length of impurity trace is not more than 3mm, the depth is not more than 1.5mm, and quantity of the trace is not more than one. The deformation is not more than 2mm. |

| Diameter | Inflating Pressure(Mpa) |

| 200mm | 0.07 |

| 250mm | 0.05 |

| 400mm | 0.04 |

| 500mm | 0.035 |

| 600mm | 0.03 |

| 700mm | 0.027 |

| 800mm | 0.026 |

| 900mm | 0.025 |

| 1000mm | 0.02 |

| 1200mm | 0.012 |

| 1500mm | 0.012 |

| 2200mm | 0.005 |

Into the mold

A. Preparation before entering the mold:

Before entering mould, the culvert balloon need to be inflated on ground and check if it is leaked or damaged in last using, to ensure that the inner mold of the culvert balloon is intact, so as to avoid causing quality hazards in the process of pouring concrete.

With the steel wire head tied to the cage facing outward, do not bend it towards the inside diameter, so as not to puncture the culvert balloon or cause air bag leakage.

Apply the soap powder water evenly on the surface of the culvert balloon for 3 times (the soap powder water has an ideal effect as the mold release agent, and the soap powder mixed with water = 1:20) to reduce the mold withdrawal resistance and facilitate the mold release.

B. Cast the concrete cushion at the bottom of the steel cage first, then use the rope to pull the culvert balloon into the steel cage (do not use the wire rope to directly contact the culvert balloon, so as to avoid damage to the inner mold of the culvert balloon), and place the inflatable mouth outside.

C. When entering culvert balloon, it should be noted that the longitudinal interface of the coat should be placed upward to reduce the friction between the outer plastic film and the concrete when the culvert balloon is pulled out.

Inflating

A. After entering mould, open the inlet valve and inflate with an air compressor.

Please use our supplied pressure gauge to test the pressure in the process of inflation, the inflated pressure depends on its specification. When it is inflated to the stated pressure, please close the valve and stop inflating. (Inflating pressure is shown on rubber culvert balloon or specification.)

B. Before using the culvert balloon, every culvert balloon need to be tested outside to get the needed time of getting stated pressure, then according to the initial setting time of concrete to confirm needed number of air compressor for guaranteeing that the concrete of plate girder vertical rib and upper parts can be pouring before initial set of concrete, the final purpose is to avoid to form construction joint, then guarantee no any joint of every plate girder.

C. The airbag inner mold shall be alternately inflated until the operating pressure is reached.

D. Noted that inflation mustn't be over stated pressure.

Fix and cast concrete

A. When concrete is poured, under the action of the inserted vibrator and concrete, the culvert balloon is easy to float, which affects the construction quality of the precast hollow board.Positioning rebar must be used for upper, lower, left and right fixation (generally DN250 culvert balloon stirrup spacing of 80cm, if the diameter is increased, the spacing should be correspondingly reduced). Next, five strips of steel plate are evenly mounted on the top of the rubber inflatable core die, and the clamp pressed on the strip steel plate and locked with the side die bolt. This method not only improves the thickness and uniformity of the roof, but also solves the problem of the thickness and uniformity of the web.

B. The casting method of concrete is basically the same as that of solid construction.

Pay attention to using ramming rods to vibrate symmetrically from both sides to prevent the left and right displacement of the inner mold of the airbag.Do not touch the inside mould of airbag during vibration to avoid damage.

C. After that, it is necessary to check and inflate the mandrel regularly, so that the mandrel can maintain stable air pressure during the whole concrete casting process.

Pulling culvert balloon down:

A. After concrete final set, please open outlet valve and then the culvert balloon can be pulled out form plate girder.

B. The time of pulling culvert balloon out depends on the water cement ratio, cement mark and environment temperature. So careful observation is necessary in concretion and the culvert balloon should be pulled out in reasonable time.Earlier pulling out will lead to the upper concrete sink, if later, it will be little difficult to be pulled out and will damage the culvert balloon possibly.

1. When the core of the culvert balloon is inflated, there is back pressure. Do not inflate to the rated pressure at one time. Pay attention to the change of the pressure gauge during concrete pouring, and do not over pressure.

2. The air release time of the culvert balloon core mold is related to the construction temperature. Generally, after the completion of concrete casting, the finger on the concrete surface can be pressed out fingerprints and the concrete can be deflated without deformation.

3. The use of the culvert balloon inner mold must brush the isolation agent(soap powder water), in order to reduce the mold resistance, the culvert balloon inner mold can not use oil to replace the isolation agent, on the one hand the oil on the rubber erosion, on the other hand the oil will pollute the steel bar.Dilute with soap powder water, the ratio of soap powder to water is about 1:20.

A. After using the culvert balloon, it need to be brushed and washed immediately(nylon brush is the best), some concrete spot can be struck off by blunt carefully.

B. The culvert balloon need to be stored in aeration-drying environment and avoid to be shined directly.

C. It can not touch with any oil and other organic solvent.

D. When using, please protect the culvert balloon from punctured by the nail, steel head and other sharp objects.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.