High damping rubber bearing, also known as HDRB or HDRB isolators, is a kind of seismic isolation bearing similar with lead rubber bearing. Made from special rubber with excellent damping attribute and layers of steel, the HDRB isolators have excellent flexibility,vibration reduction ability and high restoring ability. Thus it is an important component of seismic isolation system and can effectively reduce the bridge and building structure damage caused by earthquake.The high damping rubber bearing itself performs the isolation function and does not need to configure other devices, so the maintenance and management cost is low.

As a leading high damping rubber bearing manufacturer, Yongxi provides all kinds of best quality Seismic Isolation Bearings for bridges, seismic isolation device and LRB for bridge. For detailed information and custom service, welcome to contact us!

Product Detail

Working principle of high damping rubber bearing

By producing large deformation and small rigidity, the high damping rubber bearing has excellent seismic effect during the earthquake.As the elastic stiffness of the bearing depends on its deformation degree. When the deformation is small, the stiffness will be large. The high damping rubber bearing has excellent seismic isolation function by this principle.

Characteristics of HDRB isolators

The hysteretic characteristic (load deformation curve) of high damping rubber bearing is full, which can play an isolation effect for wind vibration and large, medium and small earthquakes.

The high damping rubber bearing itself performs the isolation function and does not need to configure other devices, so the maintenance and management cost is low.

After a large earthquake, the high damping rubber bearing will not produce residual deformation, and the characteristic change is very small, so it does not need to be replaced.

The elastic properties and damping properties of high damping rubber bearings have little dependence on temperature, that is, they are less affected by temperature, so they are suitable for a wide range of fields.

The internal EPDM rubber is completely protected which is resistant to the ozone and ultraviolet, so it has better aging-resistant ability.

HDR high damping rubber has the same superior creep performance as natural rubber.

HDRB Applications

High damping rubber bearing is widely applied in the quake-prone areas for bridge, building and other construction structures.

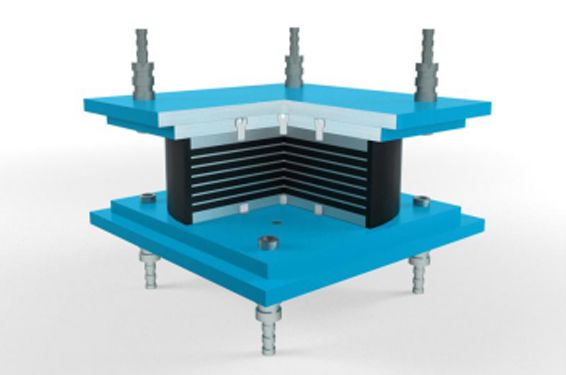

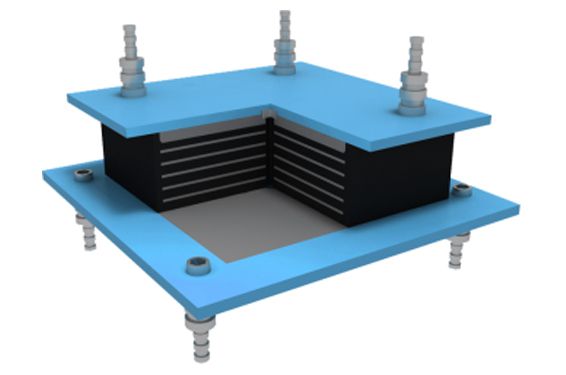

Classification of high damping rubber bearings by structure

According to the different seismic technical performance, HDR series bearings can be devided into two type by structure difference

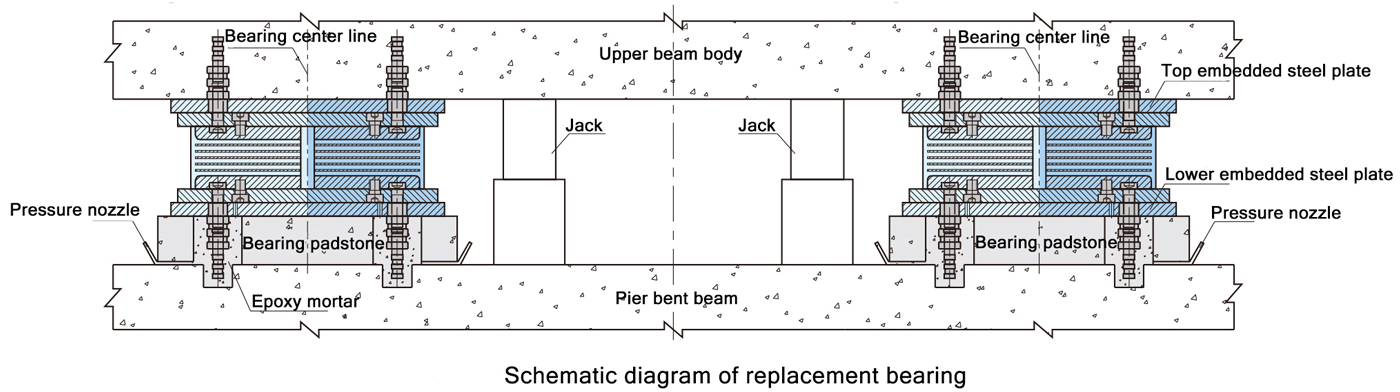

Sleeve and anchor bolt are used between the support and pier and beam. Embedded steel plates are set on the top and bottom of the support. Anchor bolts are used between the upper and lower support steel plates and the sleeve, and matching welding is used between the upper and lower embedded steel plates and the sleeve.

Sleeve and anchor bolt are used to connect the support with pier and beam. No embedded steel plate is set at the bottom of the support. Anchor bolt is used to connect the lower seal steel plate and the sleeve. Shear tenon is used to connect the upper embedded steel plate and the upper seal steel plate, and matching welding is used between the upper embedded steel plate and the sleeve

Material of HDRB isolators

The high damping rubber bearing adopts the newly developed natural rubber, which has good creep characteristics. The surface is covered with EPDM to protect the internal rubber from the influence of ozone and ultraviolet light, and has better aging resistance.

Materials testing and finished HDR testing process are strictly controlled.

For details, please contact us directly.

Precautions for installation of HDRB

Check whether the pier and abutment position corresponding to the bearing is consistent with the bearing specification

Check whether the support connection is normal, but do not loosen the connecting device arbitrarily

Check the support identification and installation direction to eliminate the wrong installation direction,

Check that the upper and lower surfaces of the support close to the concrete and cement mortar must be free of dust and oil stains.

Performance requirements of grouting materials

The grouting material used in the installation of high damping bearing is non shrinkage epoxy resin mortar

Performance requirements of non shrinkage epoxy resin mortar for grouting

| Items | Technical Index | Items | Technical Index | |

| Tensile strength | 8 h | ≥20 | mobility, | ≥220 mm |

| 12h | ≥25 | Temperature range | +5~35°C | |

| 24 h | ≥40 | Initial setting time | ≥ 30 min | |

| 28 h | ≥50 | Final setting time | ≤ 3 h | |

| 56d and 90d | No reduction | Shrinkage | <2% | |

| Bleeding | Non Bleeding | Expansion rate | ≥ 0.1% | |

When high damping bearing is adopted, the concrete grade of pad stone shall not be lower than C40, and the height difference of four corners on the top surface of pad stone shall not be greater than 2mm,In order to facilitate installation and maintenance, the height of pad stone shall not be less than 100mm.

Send A Message

Whether you'd like to get more info on what, why and how we do what we do, need help with what you're creating,would like to partner up or just say hi!---we'd love to hear from you.